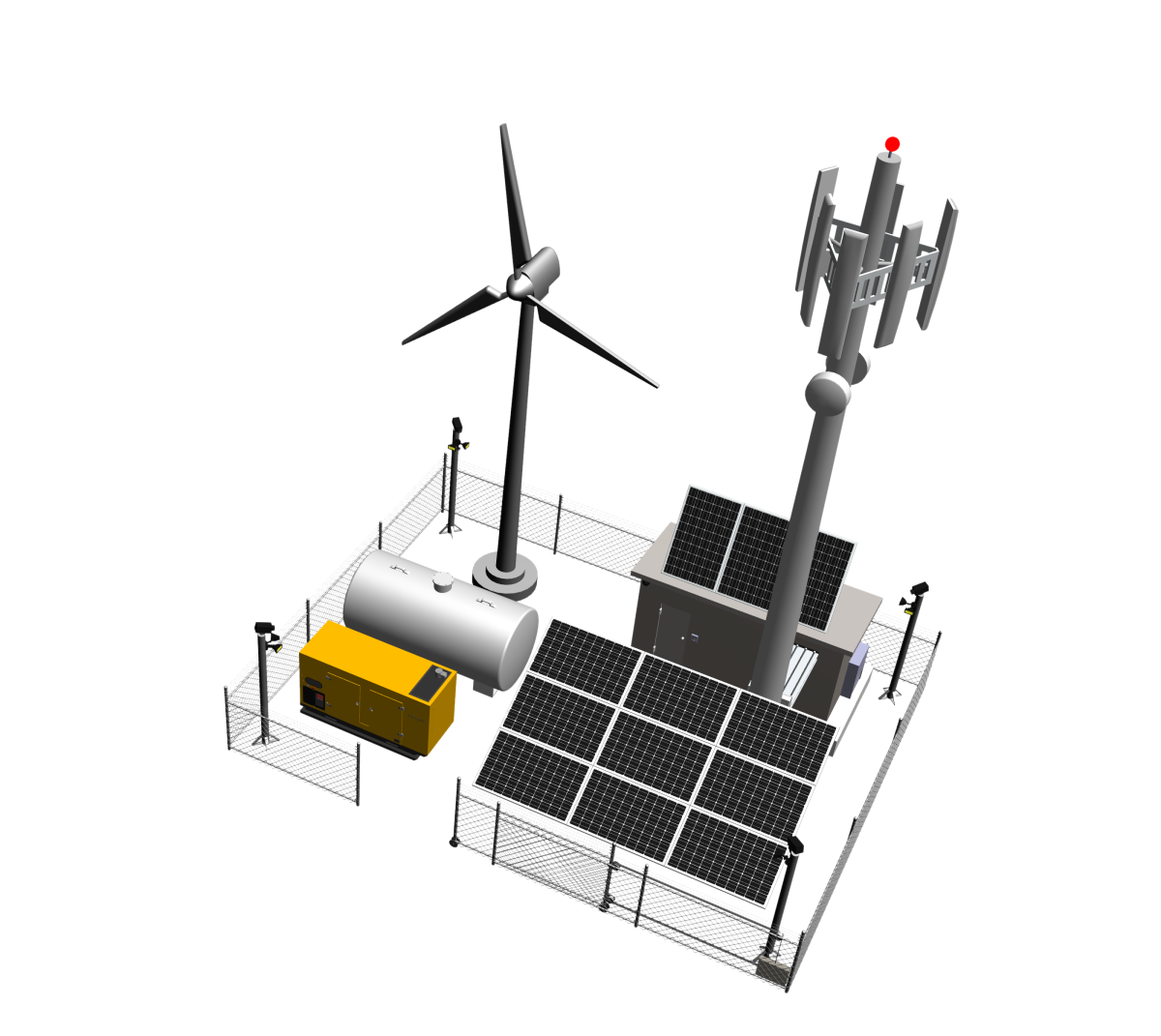

ecoSENTRY

Be In Charge

Know.

Now.

Optima’s ecoSENTRY application monitors GENSETs, energy levels, fuel tanks and sensors.

The app also tracks AC and DC power systems, and a host of environmental readings.

It immediately relays any abnormal and out-of-bounds conditions.

ecoSENTRY provides complete remote site visibility.

The application time stamps each detected event and sends out real-time alerts.

It also keeps running totals of all event counts and statistical data points.

This aids operators trying to stay within allocated budgets.

It identifies abuse patterns, and helps develop effective countermeasures to prevent future losses.

A Vital Part Of Optima’s

Complete

Site Management

Solution

To learn more about Optima’s complete facility monitoring package, simply roll over the markers shown below.

Wind Turbine

Fuel Level

Tank Monitoring

GENSET Power

Battery Health

Flood Lights

IP Cameras

Intrusion Detection

Gate Access

Remote Access

Green Energy

Photovoltaic Array

Tower Lights

Microwave Radios

Mains Power

SNMP/SMS Alerts

Occupancy/

Heating

Shelter Access

DC Power/

Battery

HVAC/Free

Air Cooling

Ventilation Control

Legacy Devices

Water/Leakage Sensor

Environmental Logging

Humidity,

Smoke,

Vibration,

Sunlight,

Pressure,

Windspeed.

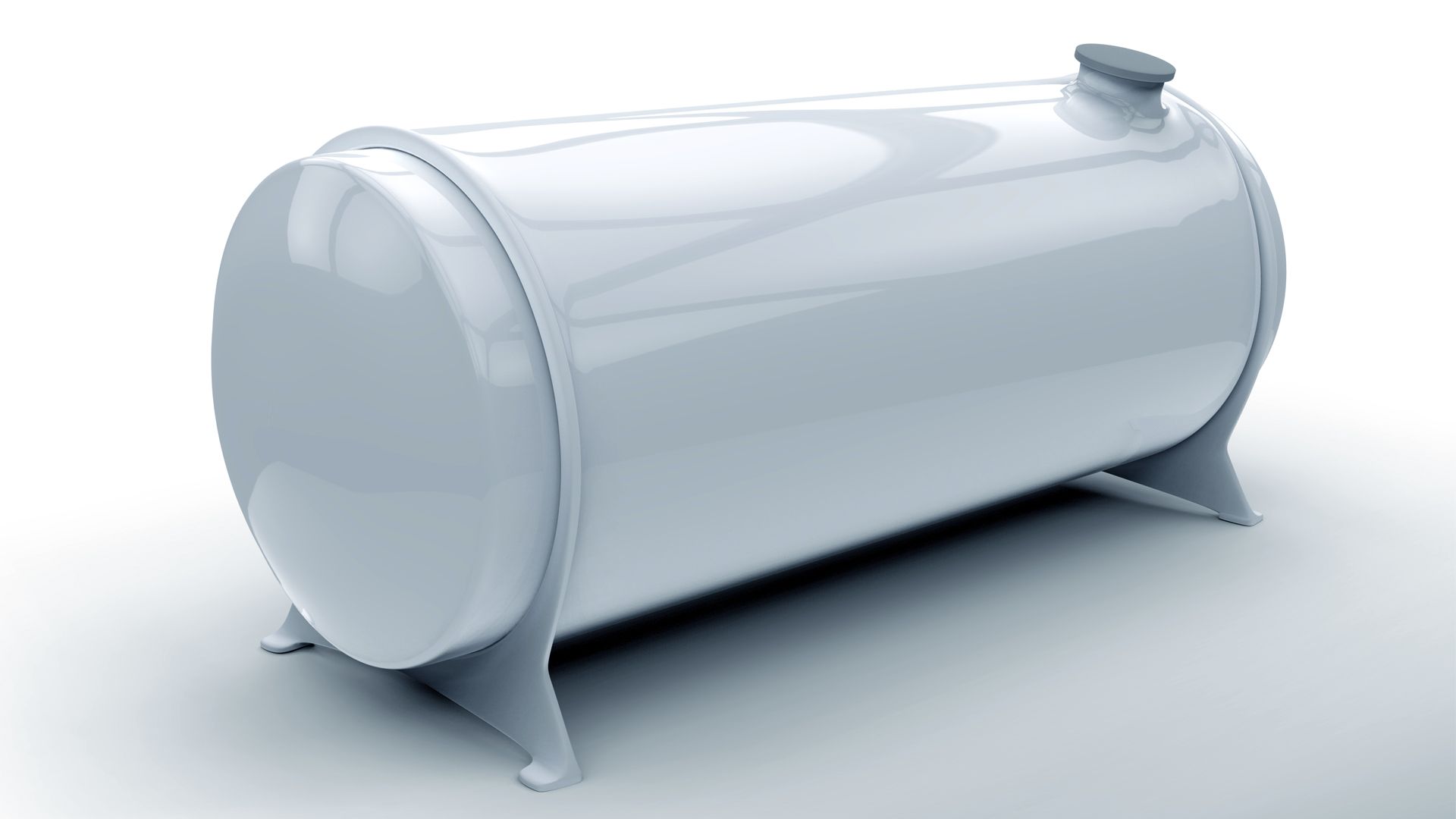

Supports Capacities Up To 100,000L.

Flexible Tank

Shapes & Sizes

ecoSENTRY works with a wide variety of diesel and LPG tanks:

- Horizontal or vertical cylinders,

- All with various end caps,

- Spherical or ellipsoid shapes,

- Rectangular or oval.

Accurate & Precise

High-Resolution

Fuel Sensing

Optima’s ultra high resolution level sensing technology eliminates guess work. The ecoSENTRY application supports:

- Rod-style/analog sensors,

- Float sensors,

- LPG gauges,

- Ultrasonic,

- Hydro-static, or

- Serial fuel level sensors.

Avoid Run-Dry Situations

Route Your Tanker Trucks

ecoSENTRY always reports the volume of fuel consumed and the amount of fuel left in a tank.

This makes fuel refill scheduling easy, avoiding costly ‘Run-Dry’ situations. Route tanker trucks to sites with the most urgent requirements first.

Approve With Ease

Correlate Vendor Claims

The application also helps during fuel verification procedures. Approve refill claims with confidence.

Correlate fuel vendor claims with the statistical data accumulated by the ecoSENTRY app.

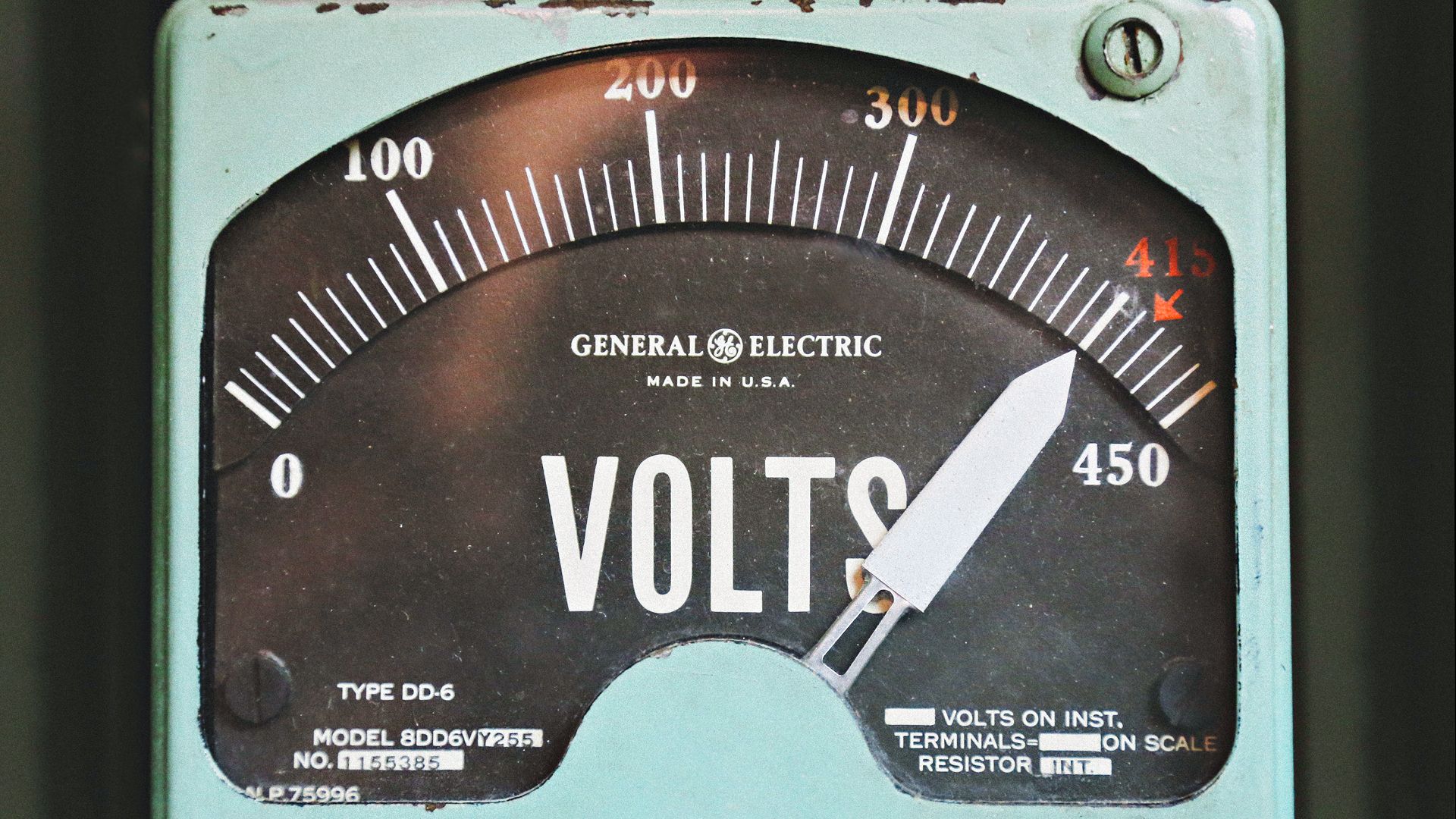

AC Or DC Monitoring

Manage Your Energy Sources

Energy monitoring tracks all relevant multi-phase AC, MAINS and DC parameters.

Generates graphs and statistics covering the last 24 hours, current week and past 30 days.

ecoSENTRY facilitates DC bus monitoring using multi-load DC meters.

This function supports logging of up to 10 discrete DC loads.

Hybrid sites with wind turbines and solar/photo-voltaic arrays are covered as well.

Automatic GENSET

Exercise & Maintenance Tracking

The ecoSENTRY application can carry out automatic GENSET exercises. It monitors engine idle times. And then initiates the GENSET exercise at the correct time-of-day.

It manages all aspects of the exercise — only calling for required ones. ecoSENTRY also tracks the generator engine run time, posting maintenance requests as needed.

Quick Deployment

Easy Hook-Ups

The ecoSENTRY app only requires a few external connections and sensors to run.

This eases rapid deployment, as the app handles all complex computations internally.

Get The Full Picture

Insightful Dashboards

Optima also offers a special dashboard & reports package for the ecoSENTRY application.

Ask for the available Optima NMS and Optima Quantum Report Generator options.

Logs & Analytics

Better Business Intelligence

Optima’s ecoSENTRY solution supports full remote statistics collections via SNMP. This makes it easy to integrate with enterprise data warehousing or analytics platforms.

ecoSENTRY stores all log files as CSV files to help with post-processing — allowing ‘copy & paste’ operations into any popular spreadsheet program.

And with a whole complement of ecoSENTRY reports, you will always be one step ahead.

Ordering / Documentation

| 3000-T560001A | ecoSENTRY App (incl. licenses) |

| 2000-P180035A | Outdoor Surge Protector (RS-485/24VDC) |

| 2000-H240002A | Ultrasonic Level Sensor (2.1m/0-10VDC) |

| 2000-H240003A | Ultrasonic Level Sensor (2.1m/4-20mA) |

| 2000-H240005A | Ultrasonic Level Sensor (4.0m/0-10VDC) |

| 2000-H240006A | Ultrasonic Level Sensor (4.0m/4-20mA) |

| 2000-H240014A | Hydrostatic Pressure Sensor (0-200mBar) |

| 2000-H240007B | 3-phase AC Power Monitor (w/ enclosure) |

| 2000-H240013A | 5-load DC Power Monitor |

| 2000-H240018A | HPS TERMINAL BOX |

| 2000-H240022A | Zener Barrier |

| 2000-H240023A | Intrinsic Safety Barrier (RS-485) |

| 2000-H240024A | Intrinsic Safety Barrier (Power) |

NOTE: Intrinsic Safety/Zener Barriers are strongly recommended when monitoring any type of equipment in hazardous zones. The HPS TERMINAL BOX is required for all Hydro-static Pressure Sensors installations. HP sensors may be installed through top mount tank openings 1″ in diameter or larger. Consult factory for assistance with available/custom clamping options. A RS-485 Surge Protector should be installed where the MODBUS wiring exits the building and is routed to outdoor equipment (such as solar, wind controllers, or power meters and converters). CTs/hall sensors are required for power monitoring and are not included with the AC/DC Monitors. Consult factory for pricing and availability.

Specifications subject to change without prior written notice. All referenced trade names are either trademarks or registered trademarks of their respective companies.